Leading & Reliable Neodymium Magnet Manufacturer

Years

Professional neodymium magnets manufacturer

countries

Market presence throughout Europe & North America

Clients

Close partnership and highly regarded

Equipments

Sophisticated equipment and sufficient productivity

Neodymium Magnets Wholesale

GP Magnets manufactures a full range of neodymium magnets. They feature strong magnetic strength, heat resistance and durability. We have years of experience providing our customers with top quality products in the industry.

Neodymium

Fishing

Magnet

Neodymium

arc

Magnet

Neodymium

ball

Magnet

Block

Countersunk

Magnet

Neodymium

ring

Magnet

Neodymium

block

Magnet

Custom

Shapes

Magnet

Neodymium

rubber

Magnet

Plastic

Coated

Magnet

Wireless

Charging

Magnet

Neodymium

rod

Magnet

Magnetic

Button

Fulfill Your Custom Magnet Needs

We can produce any magnet with a tolerance within 0.05 mm. GPmagnets is a full line of neodymium magnets manufacturer. We have serviced the worlds leading producers and customers from the most diverse industries, from motors to communications, from wind power to industrial automation.

Receiver Magnets

Vibration Motor

Haptic feedback motors

Microphones

Sensors

Motors

Actuators

Servo motors

Catheter Navigation Systems

Surgical Instruments

Blood Analysis

MRI Components

air conditioning

transmission & braking

seat, camera & other sensors

Speakers & radios

Magnetic gyroscope

Magnet fishing toys

Magnetic Puzzle

Magnetic toy car

magnetic therapy necklaces

magnetic therapy massagers

magnetic therapy shoes

magnetic therapy bracelets

One-Stop-Shop

Neodymium magnet manufacturing & custom solutions

Based on our manufacturing capacity, advanced technology and equipment, quality control measures, and production process, we are able to supply precision neodymium magnets at competitive prices within a short lead time.

Custom Requirements

Start by provide your requirements for custom neodymium magnet product. This can include information on the magnet’s size, shape, strength, coating, and any other special features that the customer may need.

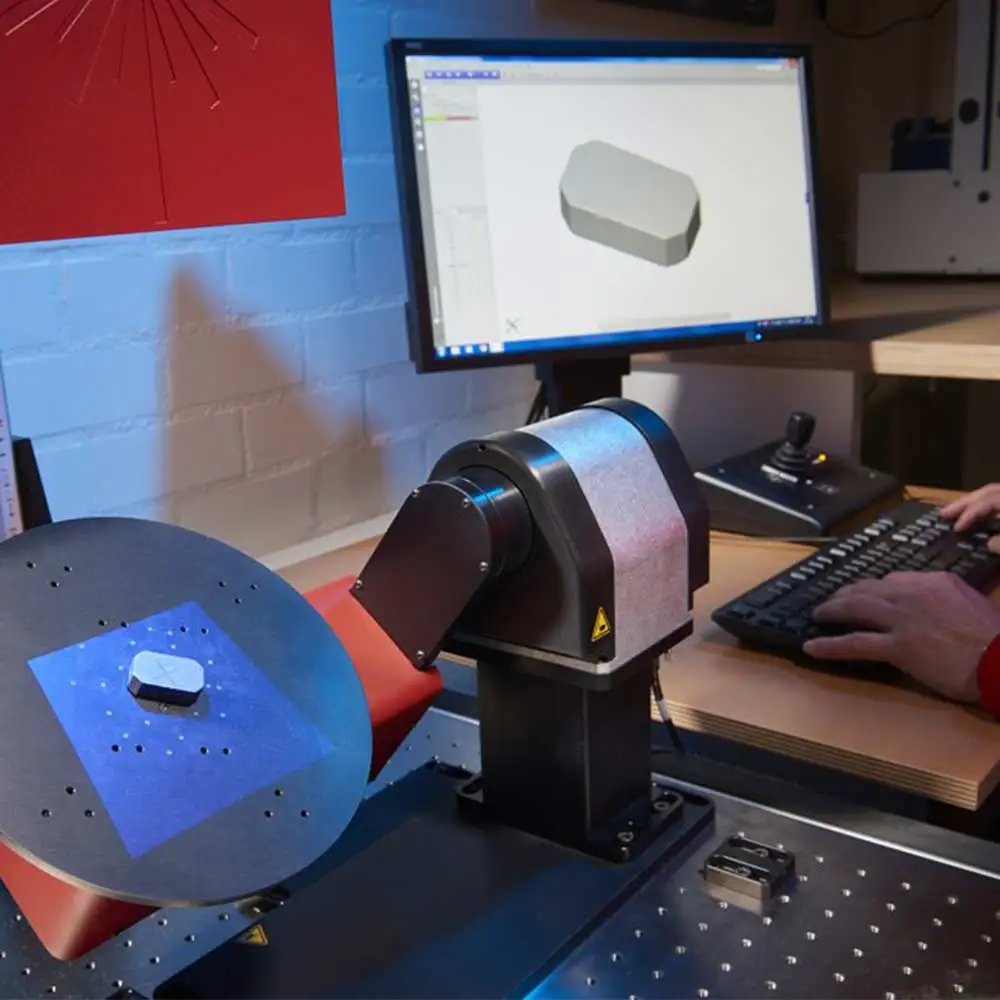

Design the Magnet

Based on the your requirements, design the magnet using specialized software such as SolidWorks or AutoCAD. This will allow our to create a 3D model of the magnet, which can be used to verify that it meets the your requirements.

Select the Materials

Choose the appropriate neodymium magnet materials for the specific application of the custom magnet, as well as any other materials needed for the manufacturing process, such as adhesives or coatings.

Fabricate the Magnet

Using the design and material selections as a guide, begin fabricating the magnet. This may involve cutting and shaping the neodymium magnet material, applying coatings, and any other necessary steps to create the final product.

Test & Inspect the Magnet

Once the magnet has been fabricated, test and inspect it to ensure that it meets the your requirements. We measuring the strength and magnetic field of the magnet, as well as any other quality control tests.

Package & Deliver the Magnet

Once the magnet has been tested and approved, package it carefully to ensure that it is protected during shipping. We are sure to include any necessary documentation, such as specifications or instructions for use, with the magnet.

Our Reliable Capabilities

GP Magnets

Good power magnetic products Limited

Good Power Magnetic Products Limited is proud to be one of the largest suppliers of magnetic products in China. Our incredibly wide range allows for the selection of magnets of various sizes, strengths, shapes and functions. Our small magnets allow for precise applications, often used in manufacturing processes and integrated into mechanical objects and tools. Depending on the strength of the magnets, they can be used in different ways.

Sourcing Neodymium Magnet

from GP Magnets

Sourcing magnets from the world’s best magnet supplier saves you time and money. From strong, neodymium cylindrical magnets to spherical magnets, GP Magnets can help you find the perfect option for your application.

what makes us different

Where we add value

Rich production experience

With 15 years of experience in manufacturing magnets, we understand the requirements of each customer.

high precision process

Thanks to our team of professional engineers and equipment, we can control the accuracy of our products to 0.05mm.

Senior technical team

We are equipped with an elite technical team of 25 people in the magnet industry, and we solve all your problems.

unrivaled quality

We have international standard production lines, 350 sets of advanced production equipment and strict quality control.

Simplified process

Abandon the complicated order process, avoid wasting time on application forms and deliver quality products to customers.

efficient service

From pre-sales to manufacturing and after-sales, we will provide tailored solutions based on your design and quotation within 24 hours.

Our happy customers

They trust GP Magnets

Fernando Pegoraro

United Kingdom

We have been working with GP Magnets for 8 years and it is our best supplier of neodymium magnets with the best price/performance ratio.

Leon Firer

Australia

The best part for me is that Gp Magnets, actually accepts small orders, which makes my sales very easy.

Sam Johnston

United States

Gp Magnets Well done. I only had to list our needs and they understood our product immediately, saved a lot of time and were a pleasure to work with.

join the success

These are just a few of our successful clients

we’re here to all your questions

What are the advantages of our products, is there a minimum MQO?

Entity manufacturer, perfect service, high-quality raw materials, stable structure, mature technology, advanced equipment, and the best cost performance. We do not have a minimum order quantity.

What are the factors that affect the price of magnets?

Material cost: The higher the performance requirements, the higher the cost, such as NdFeB magnets, the price of N45 is much higher than the price of N35;

Processing cost: the more complex the shape, the higher the processing cost;

Dimensional tolerance: The tighter the tolerance, the higher the processing cost; the smaller the batch, the higher the processing cost.

What are the application scope of the magnets we produce

Our products are widely used in electronic and electrical components, TWS headphones, motors, speakers, compasses, maglev trains, induction cookers, generators, toys, luggage, automotive new energy, underwater operations, aerospace and other industries. Inside and outside, and won unanimous praise from customers.

Why some customers have weakened or disappeared after receiving the magnet products?

The biggest factor affecting magnetic attenuation is temperature. The maximum working temperature of M series magnets is 80°C. If the container is shipped by sea in summer, the temperature of the container is too high, which is expected to reach 70-80°C, which will cause the magnetic force to weaken or disappear.

What information do I need to provide when ordering magnets?

The biggest factor affecting magnetic attenuation is temperature. The maximum working temperature of M series magnets is 80°C. If the container is shipped by sea in summer, the temperature of the container is too high, which is expected to reach 70-80°C, which will cause the magnetic force to weaken or disappear.

What are the material grades of neodymium magnets?

Neodymium magnets are available in different grades such as N35, N38, N42, N52, N35UH.. etc. Each shape of neodymium magnet is graded according to its material. The magnetic force increases with the level and size of the magnet (the number after the “N”). The current highest grade is N52. The letter after the grade represents the high temperature resistance of the magnet. Magnets without letters after the grade are the standard temperature for magnets and the most widely used on the market.

How to choose the high temperature resistant magnet correctly?

1. Choose NdFeB high temperature resistant magnets between 80°C and 230°C working temperature,

2. Choose samarium cobalt high temperature resistant magnets between 250 degrees and 350 degrees

3. At present, only ferrite magnets or AlNiCo magnets can be selected for high-temperature magnets with a working temperature above 350 degrees.

Can you produce customized products, customized process

We can customize different types of magnets, and our engineers will provide you with a suitable magnetic solution according to your requirements. The customized process is pre-sales consultation, manufacturer quotation, product proofing, sample confirmation, contract signing, production, settlement and delivery, after-sales service

Request a quote for your next magnetic project

Become a partner of GP Magnets and astounding quality & unbelievable costs bring you more profits.