Gp Magnets

Custom Neodymium Magnet Solution

GP Magnets offers a wide variety of custom, high quality neodymium magnets for any application. From prototyping to large quantity orders – experience our unrivaled selection of powerful neodymium magnets today!

#1 NdFeB magnet custom solution provider

Over the past 15 years, we have customized more than 1000 different sizes and shapes of magnets for many industrial applications around the world.

- 18% of our customers are the top 5 regional leaders in the industry in terms of annual turnover.

- 32% of our customers are fast growing companies with annual revenue growth rates of 30% and above.

- 41% of our clients have been in business in their current industry sector for more than 5 years.

- 54% of our customers have been working with us for more than 10 years on magnetic solutions.

- 69% of our customers trust us to provide more than 50% of their magnetic product purchases.

Magnet Solution

Whether you’re looking for advanced engineering support or innovative components, GP Magnets has everything you need when it comes to bespoke magnet solutions. Take advantage of exceptional quality control measures enabled by cutting edge processes developed at GP Magnetics; get superior products that last longer and withstand tough conditions without breaking the bank!

1000+ Custom Sizes

Customize the size, thickness and orientation to match your creative application in all aspects.

Custom Shaped Magnets

Mold forming process to produce into rolls, sheets, strips, blocks, rings and various complex shapes.

Custom Magnetic Assemblies

In addition to generating high quality neodymium magnets, our efficient assembly line helps you to save more time and labor costs.

Custom Needs

How to customize my magnets?

Please tell us the size, grade, surface coation and quantity of the magnet, the details are as follows. At the same time, you will get the most reasonable quotation quickly.

01

Custom size

GP Magnets offers a range of custom neodymium magnets, including rectangular, square and ring shaped options available in a variety of sizes up to 150 mm length per side, thicknesses ranging from 0.5mm to 12mm and strengths as high as 140MGOe (or 14 Tesla).

- Round Magnet : Diameter x Height

- Ring Magnet : Outer Diameter x Height - Inter Diameter

- Block Magnet : Length x Width x Height

- Special Shape Magnet : Drafts or drawings will be appreciated

02

Grade Choose

The grade of a neodymium magnet refers to its strength. We offer a range of grades, from N35 to N52, to meet the different requirements of our customers. The higher the grade, the stronger the magnet.

- Material: Sintered Neodymium Iron Boron

- Dimensions: Customized

- Tolerance: Standard +/-0.05mm, Min.+/-0.01mm

- Magnetic Properties Grade Max. Operating Temperatures

N35-N52 80°C (176°F)

33M- 48M 100°C (212°F)

33H-48H 120°C (248°F)

30SH-45SH 150°C (302°F)

30UH-40UH 180°C (356°F)

28EH-38EH 200°C (392°F)

28AH-35AH 230°C (428°F) - Remanence(Br): 11,300 Gauss — 14,800 Gauss

- Coercive Force(Hcb): 10,000 Oersted — 12,600 Oersted

- Intrinsic Coercive Force(Hcb): 11,000 Oersted — 36,000 Oersted

- Magnetic Energy Product (BH): 33M GOe — 53M GOe

03

Magnetizing Direction

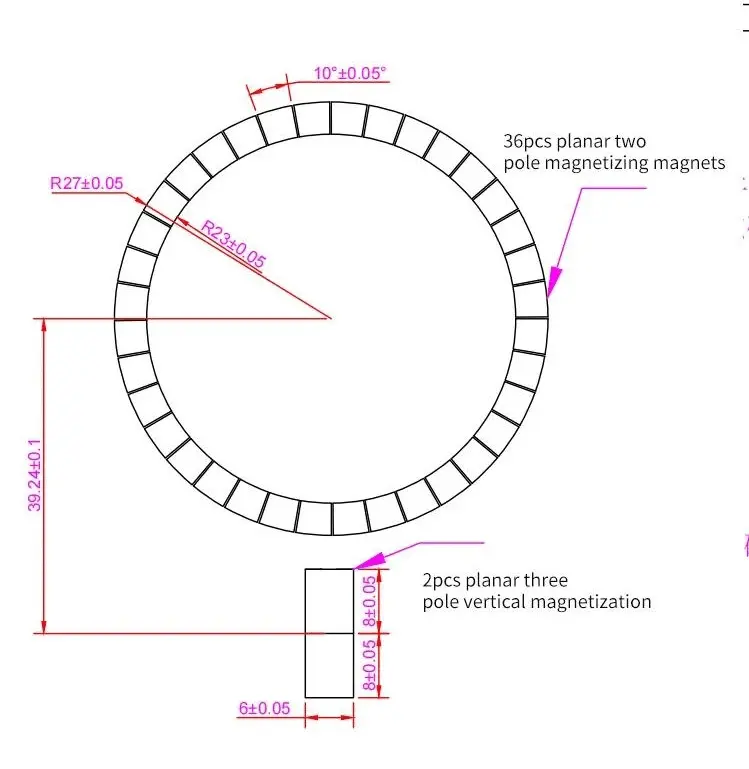

Neodymium magnets are generally magnetized in the direction of thickness magnetization, axial magnetization, radial magnetization, multi-pole magnetization, radial magnetization and custom magnetization, depending on your product requirements.

- Disc, cylinder and Ring shape magnet can be magnetized Axially or Diametrically.

- Rectangle shape magnets can be magnetized through Thickness, Length or Width.

- Arc shape magnets can be magnetized Diametrically, through Width or Thickness.

- Special direction of magnetization can be customized as required.

04

Surface Coation

Neodymium magnets are very reactive and can corrode easily. To prevent this, we offer a range of surface coatings, including nickel, copper, gold, and epoxy. The coating also enhances the magnet’s appearance and can provide additional protection in certain applications.

| Electroplating | Surface | Coating | Thickness | Color |

| (Microns) | ||||

| Passivation | 0-1 | Silver Grey | ||

| Nickel | Ni+Ni | 10-20 | Bright Silver | |

| Ni+Cu+Ni | ||||

| Zinc | Zn | 8-20 | Bright Blue | |

| C-Zn | Shinny Color | |||

| Tin | Ni+Cu+Sn | 15-20 | Silver | |

| Gold | Ni+Cu+Au | 10-20 | Gold | |

| Copper | Ni+Cu | 10-20 | Gold | |

| Customized coating for Neodymium Magnet are available. | ||||

05

Quantity (Samples are available)

In order to quote the exact competitive price, the quantity for the magnet is essential. We work with you to determine the quantity of magnets they need. We are able to produce custom orders in large or small quantities, depending on the needs of the customer.

With a monthly production capacity of over 20 million, GP Magnets is able to take on orders for both large purchases and small to medium volume production.

120

employees

20

technical teams

350

equipment

20 million

monthly production

VALUE ADDED SERVICES

Want to get your magnetic product to market fast? We specialize in quick proposals and fast production, and we know how to make the process easy. We will exceed your high expectations for quality and service to ensure your equipment is delivered on time. GP magnets’ goal is to give you peace of mind!

Market Analysis

Our R&D department is focused on analyzing global trends and new material development, which helps us stay ahead of the curve in providing the quality magnets that the market expects.

Prototype Development

Prototype development allows customers to test and evaluate magnets before placing an order. This service saves customers time and money by identifying any potential problems prior to production.

Customized Solutions

Offering custom design services allows customers to obtain magnets tailored to their specific needs. This service ensures that customers get the magnets they need for their unique applications, whether it is a unique shape or size or a specific application.

Magnet Assembly

Magnetic assembly services allow customers to receive magnets that have been assembled into the desired configuration. This service saves customers time and labor costs.

Supply Chain Management

Strategic cooperation with the No.1 rare earth miner in China makes us a strong and secure backing for rare earth raw material cost stability. From sourcing to logistics throughout the magnet component supply chain to ensure on-time delivery and cost effectiveness.

Packaging and shipping

Providing packaging and shipping services ensures that customers receive their magnets in good condition and on time. Contract pricing with FedEx, DHL, UPS and TNT to minimize your shipping costs.

Elevate Your Business with Professional Neodymium Magnets from GP Magnets

Discover the Difference that GP Magnets Custom Magnet Solutions Make

Why GP Magnets

Good Power Magnetic Products Limited is proud to be one of the largest suppliers of magnetic products in China. Our incredibly wide range allows for the selection of magnets of various sizes, strengths, shapes and functions. Our small magnets allow for precise applications, often used in manufacturing processes and integrated into mechanical objects and tools. Depending on the strength of the magnets, they can be used in different ways.

- 2D and 3D magnetic modeling of designs

- Rapid prototyping of designs

- Ability to manufacture any number of magnets

- Extensive product quality checks

- On-time delivery

Good Power Magnetic Products Limited

At GP Magnets, we design custom magnets to meet your specific needs. We combine ingenuity, deep expertise and a line of specialized equipment in order to provide you with the exact product you need, without sacrificing quality design and engineering.

One-stop magnet solution

From development and prototyping to production, we save you 50% of your time

15 years experience

With many years of experience in making neodymium magnets, you don't have to worry about not being able to source quality magnets.

Excellent production capacity

With 350 production facilities, 120 employees, and 25 technical team, you can receive the perfect product just by placing an order.

International Certification

With international certificates such as ISO, ROHS, MSDS, etc., we export to more than 20 countries worldwide.

Reasonable price

Magnet manufacturer located in China, from raw material to production, can save you 35% of your budget cost.

Reliable quality

With reliable quality, we have been supplying high quality neodymium magnets to more than 150 customers worldwide for more than 10 years, which is our core.

Automotive

Starter motors, control units, speakers, eddy current brakes, alternators, speedometers.

Telecommunications

Loudspeakers, microphones, telephone ringers, electroacoustic pickups, switches and relays.

Consumer electronics

DC motors, low voltage DC drives, TV speakers and audio, TV beam correction and focusing devices, CD drives, VCRs, computers, electronic clocks, analog watches.

Industrial

DC motors for magnetic tools, robots, magnetic separators, magnetic bearings, servo motor drives, lifting equipment, instrumentation and measuring equipment.

Electronic & Instrumentation

Sensors, non-contact switches, energy meter disks, electromechanical sensors, cross-field tubes, flux transfer tripping devices, dampers.

Biosurgery

Dentures, orthopedics, wound closure, gastric seals, rejection collars, ferromagnetic probes, magnetically powered artificial hearts, MRI scanners.

quickly and simply

Custom neodymium magnets step by step

We have accumulated over 15 years of experience and expertise, allowing us to work with you to enhance your brand through each step of our integration process, from consultation to final delivery.

Step 1

Custom Requirements

Start by provide your requirements for custom neodymium magnet product. This can include information on the magnet’s size, shape, strength, coating, and any other special features that the customer may need.

Step 2

Design the Magnet

Based on the your requirements, design the magnet using specialized software such as SolidWorks or AutoCAD. This will allow our to create a 3D model of the magnet, which can be used to verify that it meets the your requirements.

Step 3

Select the Materials

Choose the appropriate neodymium magnet materials for the specific application of the custom magnet, as well as any other materials needed for the manufacturing process, such as adhesives or coatings.

Step 4

Fabricate the Magnet

Using the design and material selections as a guide, begin fabricating the magnet. This may involve cutting and shaping the neodymium magnet material, applying coatings, and any other necessary steps to create the final product.

Step 5

Test and Inspect the Magnet

Once the magnet has been tested and approved, package it carefully to ensure that it is protected during shipping. We are sure to include any necessary documentation, such as specifications or instructions for use, with the magnet.

Step 6

Package and Deliver the Magnet

Once the magnet has been tested and approved, package it carefully to ensure that it is protected during shipping. We are sure to include any necessary documentation, such as specifications or instructions for use, with the magnet.

Common Questions

Entity manufacturer, perfect service, high-quality raw materials, stable structure, mature technology, advanced equipment, and the best cost performance. We do not have a minimum order quantity.

Material cost: The higher the performance requirements, the higher the cost, such as NdFeB magnets, the price of N45 is much higher than the price of N35;

Processing cost: the more complex the shape, the higher the processing cost;

Dimensional tolerance: The tighter the tolerance, the higher the processing cost; the smaller the batch, the higher the processing cost.

Our products are widely used in electronic and electrical components, TWS headphones, motors, speakers, compasses, maglev trains, induction cookers, generators, toys, luggage, automotive new energy, underwater operations, aerospace and other industries. Inside and outside, and won unanimous praise from customers.

The biggest factor affecting magnetic attenuation is temperature. The maximum working temperature of M series magnets is 80°C. If the container is shipped by sea in summer, the temperature of the container is too high, which is expected to reach 70-80°C, which will cause the magnetic force to weaken or disappear.

Neodymium magnets are available in different grades such as N35, N38, N42, N52, N35UH.. etc. Each shape of neodymium magnet is graded according to its material. The magnetic force increases with the level and size of the magnet (the number after the “N”). The current highest grade is N52. The letter after the grade represents the high temperature resistance of the magnet. Magnets without letters after the grade are the standard temperature for magnets and the most widely used on the market.

1. Choose NdFeB high temperature resistant magnets between 80°C and 230°C working temperature,

2. Choose samarium cobalt high temperature resistant magnets between 250 degrees and 350 degrees

3. At present, only ferrite magnets or AlNiCo magnets can be selected for high-temperature magnets with a working temperature above 350 degrees.

They Believe

GP Magnets

join the success

These are just a few of our successful clients

Request a quote for your next magnetic project

Become a partner of GP Magnets and astounding quality & unbelievable costs bring you more profits.

- One-stop magnet solution, from development, sampling to production

- Reasonable china magnetic parts price

- More than 15 years experience of magnetic products manufacturer china

- Fast reaction and Professional Communication