- Home

- /

- Injeciton molded magnet

Injeciton molded magnet

Injection molded magnets offer designers and engineers a material with virtually unlimited size and magnetic possibilities. Made by blending a magnetic material (NdFeB) with a polymer binder (PA6, PA12 or PPS), the magnets can then be injection molded like any other plastic. In addition to providing maximum shape complexity, these magnets can be overmolded directly onto/around existing components such as shafts or bushings, often without secondary bonding or assembly.

Injeciton molded magnets

Complex shapes, tight tolerances – directly to shafts, bushings, or any other components.

Injection molded magnets-magnetic assembly-1

Injection molded magnets-magnetic assembly-2

Injection molded magnets-magnetic assembly-3

Injection molded magnets-magnetic assembly-4

Customized injection molded magnets flexible to your design

Compared with sintered magnetic materials, injection molding magnet has the advantages of low density, high impact strength, magnetic properties controlled by magnetic powder content, good chemical stability, and will not be broken when used.

It can choose nylon, PPS, elastic plastic and other resins as the base material, mixed with NdFeB powder, and processed by plastic injection molding technology, which has unique advantages in the preparation of thin-walled, complex shape, spoke orientation, high precision magnets, and integrated combination molding.

It also has the characteristics of high material utilization and high production efficiency; it plays a key role in miniaturization, light weight, compounding, high efficiency and energy saving of electronic components.

Features & benefits of Injection Molded Neodymium Magnet

- Injection molded magnets can be of very complex shapes with high precision, typically, tolerance is+/- 0.005mm, it is suitable for high precision parts.

- By doing insert molding, magnetic material can be directly molded into or onto other assembly components without secondary assembly process

- Magnetic powder is neodymium-iron-boron (NdFeB), either isotropic or anisotropic. And Polymer binders utilized are PA12 or PPS

- Anisotropic NdFeB powder achieves the highest magnetic force as injection molded magnet. With (BH)max ranging from 1 MGOe to 12 MGOe.

- Injection-molded magnets with excellent rigidity and toughness.

- The thermoplastic resin PA6 for injection molded magnets can reach a maximum working temperature of 140°C, PA12 up to 120°C and PPS up to 180°C.

- (BH)max for injection molded NdFeB anisotropic magnets is 12 MGOe and Br is 7.5 KGs.

Injection magnets - Magnetic characteristics

Grade Properties | Remanence | Coercivity | Intrinsic Coercivity | Max. Energy Product BH(max) KJ/m3(MGOe) | Density | Relative Recoil | Temperature Coefficient | Max. Operating |

| Br | Hcb | Hcj | g/cm3 | Permeability | of Remanence | Temperature Tw | ||

| T(GS) | KA/m(KOe) | KA/m(Koe) | µr | αBr | ℃ | |||

| %/℃ | ||||||||

| BNI-3 | 0.2~0.4 | 120~240 | 480~640 | 8~24 | 3.9~4.4 | 1.2 | -0.15 | 100 |

| (1.5~3.0) | (6.0~8.0) | (1.0~3.0) | ||||||

| BNI-4 | 0.40~0.46 | 250~335 | 575~735 | 28~36 | 4.2~4.9 | 1.2 | -0.13 | 110 |

| (3.1~4.2) | (7.2~9.2) | (3.5~4.5) | ||||||

| BNI-5 | 0.45~0.51 | 280~360 | 640~800 | 37~44 | 4.5~5.0 | 1.2 | -0.13 | 120 |

| (3.5~4.5) | (8~10) | (4.6~5.5) | ||||||

| BNI-6 | 0.51~0.56 | 295~375 | 640~800 | 44~52 | 4.7~5.1 | 1.13 | -0.11 | 120 |

| (3.7~4.7) | (8~10) | (5.5~6.5) | ||||||

| BNI-6H | 0.48~0.56 | 335~400 | 1035~1355 | 40~52 | 4.8~5.2 | 1.13 | -0.15 | 130 |

| (4.2~5.0) | (13~17) | (5.0~6.5) | ||||||

| BNI-7 | 0.54~0.64 | 320~400 | 640~800 | 51~59 | 5.0~5.5 | 1.13 | -0.11 | 120 |

| (4.0~5.0) | (8~10) | (6.5~7.5) | ||||||

| BNI-5SR (PPS) | 0.45~0.50 | 300~360 | 875~1115 | 36~44 | 4.9~5.4 | 1.13 | -0.13 | 150 |

| (3.8~4.5) | (11~14) | (4.5~5.5) |

Magnetic orientation of injection molded magnet assemblies

Compared with sintered NdFeB magnets, injection molded NdFeB magnets have stronger corrosion resistance, are not easy to crack and fracture, and do not require mechanical processing such as cutting. The product has high yield, high tolerance accuracy after molding, smooth surface, good internal uniformity, uniform surface magnetic field, and strong corrosion resistance.

When charging multi-poles and the pole distance is less than 1mm, the injection molded neodymium magnets have the unique advantage. We can charge various magnets in axial, radial and planar directions according to user requirements, and adjust the charging waveform to meet user requirements, including sine wave and square wave.

Reliable custom injection molded magnet capabilities

Advanced Equipment

Our injection molding process uses state-of-the-art equipment to ensure precise and efficient production. Our machines are capable of handling high-temperature materials to produce magnets with high magnetic performance.

Customization

We offer a wide range of customization options to meet our customers' needs. Our injection molding process allows for varied designs and shapes, with tight tolerances and dimensional accuracy.

Cost-Effective Production

With our technology, we can produce complex shapes and intricate designs without expensive tooling, making it cost-effective for our customers in terms of manufacturing.

High Precision

Our injection molding process is highly precise and can produce magnets with intricate shapes and tight tolerances. We use advanced equipment such as computer numerical control (CNC) machines to ensure accuracy and consistency in every batch.

Quality Control

We use rigorous testing and quality control procedures to ensure the highest level of product quality and consistency. Our testing equipment includes gauss meters, magnetizing fixtures, and remanence analyzers, among others.

Always provide you with the most suitable injection molded NdFeB magnets

Automotive Electronics

Injection molded magnets are used to produce sensors, speedometers, and actuators for a variety of automotive applications. These magnets are manufactured to withstand high temperatures and harsh operating conditions, ensuring optimal performance and reliable operation.

Computers and Peripherals

Injection molded magnets are used in the manufacture of hard drives for computers and other storage devices. These magnets are essential for precise positioning of the read/write head, enabling fast and accurate data transfer.

Consumer Electronics

Injection molded magnets are used in the manufacture of small electronic devices such as headphones, earbuds, and microphones. These magnets help to improve sound quality and ensure optimal performance of these devices.

Industrial Equipment

Injection molded magnets play a critical role in the manufacturing of industrial equipment such as motors, generators, and machining tools. These magnets are used to create a magnetic field, enabling the efficient transfer of power in various industrial applications.

Security Equipment

Injection molded magnets are used in the production of security equipment such as access control systems and magnetic door locks. These magnets are used to create a strong magnetic field to secure doors and prevent unauthorized access.

Advertising Gifts

Injection molded magnets are commonly used in the production of promotional items such as fridge magnets, keychains, and other small giveaways. These magnets are customizable and are an effective way to advertise a brand or message.

Why GP Magnets Supplier

GP Magnets is a leading manufacturer of high-quality neodymium magnets. With over 15 years of experience in the industry, we have established ourselves as a reliable and trusted source for magnets of all shapes and sizes.

- Stable and high quality rare earth supply chain

- Free sample quality inspection

- 120 workers & 350 production machines

- Efficient production & perfect quality control process

- 15 years experience in export trade

Reasonable Costs

Our extensive experience in optimizing production management allows us to offer high quality products at much lower prices than our competitors.

Global manufacturing standards

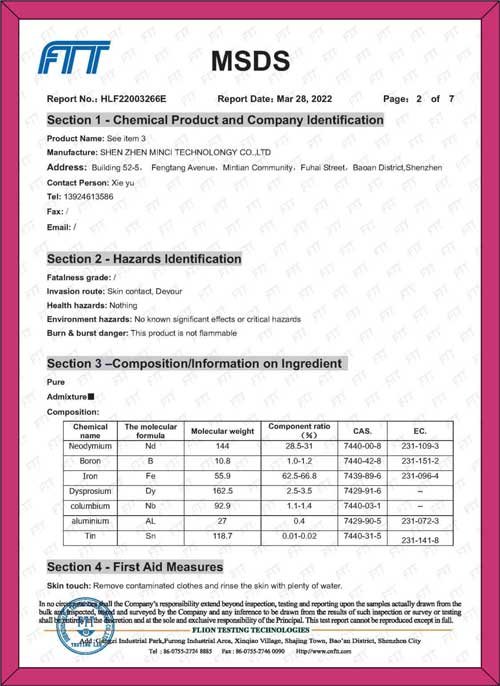

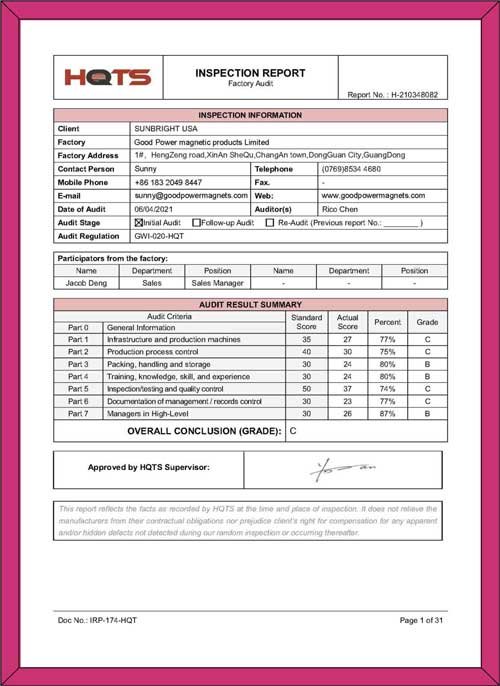

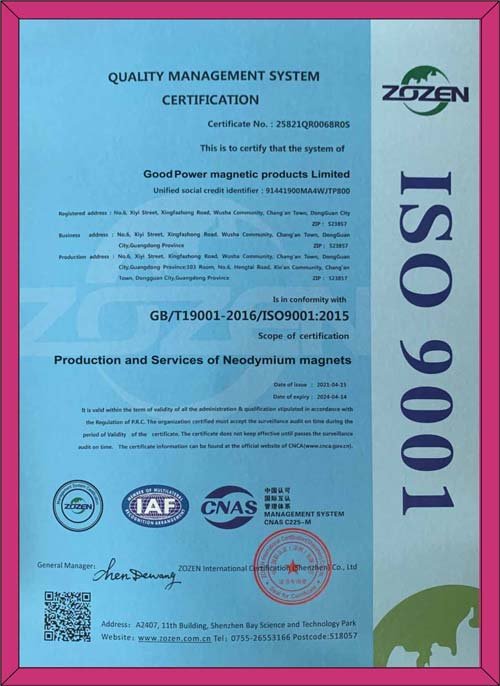

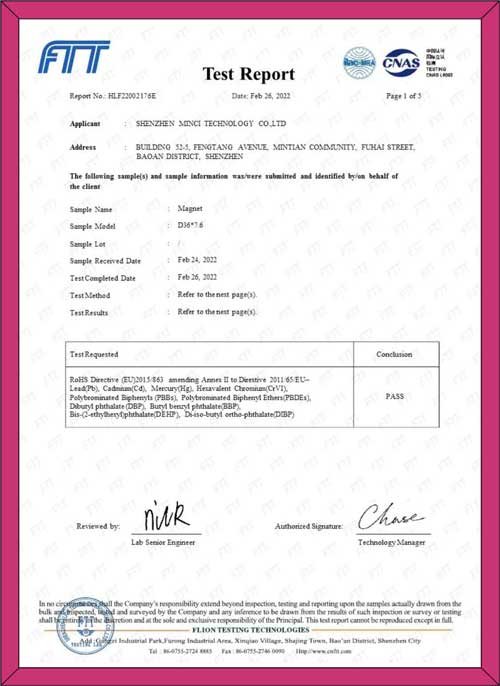

We have been in the neodymium magnet industry for 15 years. We have a low turnover of highly skilled teams of workers, many of whom have been with us for more than 10 years. Our ISO, MSDS and other certifications prove our commitment to quality.

Low MOQs

We have experience in docking large purchases while valuing orders from small and medium-sized businesses, and we are happy to help start-up companies grow, not just as business, but as partners.

Strict Quality Control

The final inspection is done in-house. Our quality control team has more than 10 quality control engineers and quality control equipment, who do nothing but final inspection of all our products before shipment.

Flexibility

We can produce custom sizes and shapes, quality, materials and packaging. We can easily meet all customer requirements outside of product specifications.

On-Time Delivery

We will never promise to deliver an order on an unreasonable schedule just to close a sale. Our customer support team will provide you with a delivery schedule prior to any purchase agreement.

What our customers benefit from

Request a quote for your next magnetic project

Become a partner of GP Magnets and astounding quality & unbelievable costs bring you more profits.

- One-stop magnet solution, from development, sampling to production

- Reasonable china magnetic parts price

- More than 15 years experience of magnetic products manufacturer china

- Fast reaction and Professional Communication