- Home

- Motor Magnets

Neodymium Motor Magnets Supplier

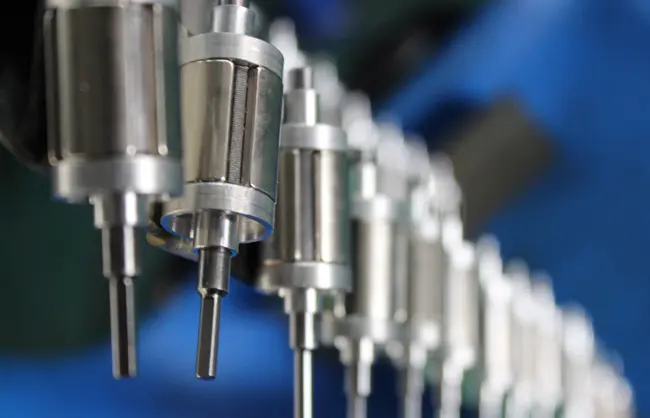

Our engineered neodymium magnets unlock new possibilities for high-efficiency motor design. With unmatched magnetic energy density, these customizable magnets advance electric motor performance through compact form factors, quiet operation, fast response times, and excellent speed control. Leveraging decades of experience, we expertly craft neodymium magnet solutions tailored to your exact motor requirements.

Neodymium magnet for motor

Neodymium magnets provide flexible customization to advance motor design and exceed application needs.

Arc Shaped Motor Magnets

Block Shaped Motor Magnets

Fan Shaped Motor Magnets

Fan Shaped Motor Magnets

Characteristics of Motor Magnets

- Item: Neodymium Motor Magnet

- Material: NdFeB

- Working Temperature Grade Temperature

N28-N48 ≤80℃

N50-N55 ≤60ºC

30M-52M ≤100ºC

28H-50H ≤120ºC

28SH-48SH ≤150ºC

28UH-42UH ≤180ºC

28EH-38EH ≤200ºC

28ah-33ah ≤200ºc - Magnet shapes: discs, cylinders, square blocks, rings, countersunk holes, tiles, trapezoids, and irregular shapes. Customized shapes available

- Magnet coating: nickel, zinc, gold, silver, epoxy, passivation, etc.

- Features: The most powerful permanent magnets with great payback in cost and performance, with the highest magnetic field/surface strength (Br), high coercivity (Hc), and can be easily formed into a wide variety of shapes and sizes. Reacts with moisture and oxygen and is usually supplied by electroplating (nickel, zinc, passivation, epoxy coating, etc.

The Use of Motor Magnets

The use of motor magnets is widespread in various industries and applications. These magnets, such as neodymium magnets, play a crucial role in enhancing the performance and efficiency of motors. They are commonly used in electric vehicles, wind turbines, robotics, industrial machinery, and more.

Motor magnets provide strong magnetic fields, high torque, and compact size, resulting in improved power density and reduced energy consumption. Their reliability and stability make them an essential component in modern motor systems.

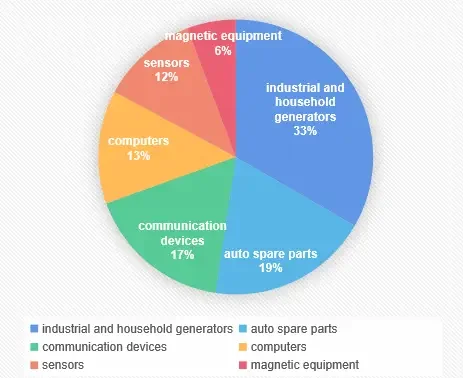

Distribution of magnet applications

- 35% for industrial and household generators, servo motors, linear motors and industrial motors, etc.

- 20%, automotive spare parts such as motors, sensors and audio.

- 18%, cellular phones and many kinds of communication equipment

- 14%, computers and information technology, digital cameras, etc.

- 12%, electronic relays, electronic controllers, sensors

Benefits of Permanent Magnet Motors

High efficiency

No power required to magnetize rotors results in less energy loss.

High power density

Compact size versus electromagnets enables smaller, lighter designs.

Maintenance

No external magnetization reduces complexity.

Noise reduction

Smooth magnetic fields lower acoustic noise.

Fast response

Quick rotor acceleration due to constant magnetic flux.

Wide speed range

Excellent speed control capacity including at low RPMs.

Permanent motor magnet customized service

Wide range of material grades

N/M/H/SH/UH/EH/TH grades.

Wide range of customized types

tile-shaped, u-shaped, circular, countersunk holes, square with holes, slotted, beveled magnets, convex, concave magnets, oval etc.

Customized Packing

Regularly packed in vacuum plastic bags, can do demagnetization treatment; also can be packed according to your requirements.

Labeling

Print logo or line mark according to your requirement.

Customized coating

nickel plating, chemical nickel plating, blue and white zinc plating, color zinc plating, epoxy resin plating, black nickel plating, gold plating, silver plating, copper plating, phosphating.

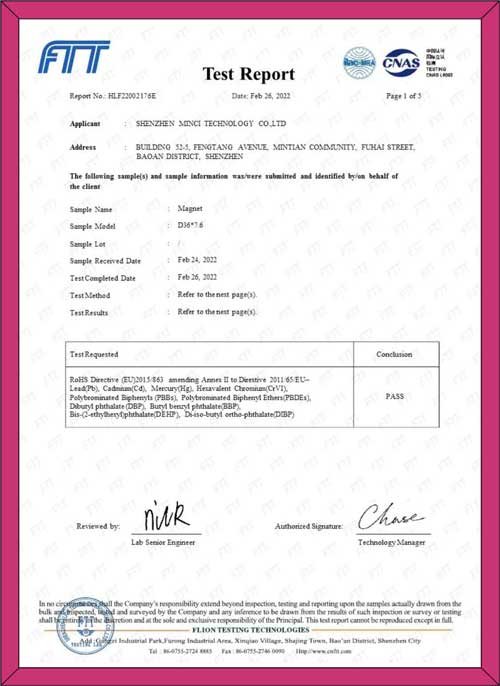

Product testing

drop test, sweat test, salt spray test, pull/absorption test, environmental protection test, film thickness test, paper tape friction test, reliability test, etc.

Why GP Magnets Supplier

GP Magnets is a leading manufacturer of high-quality neodymium magnets. With over 15 years of experience in the industry, we have established ourselves as a reliable and trusted source for magnets of all shapes and sizes.

- Stable and high quality rare earth supply chain

- Free sample quality inspection

- 120 workers & 350 production machines

- Efficient production & perfect quality control process

- 15 years experience in export trade

Reasonable Costs

Our extensive experience in optimizing production management allows us to offer high quality products at much lower prices than our competitors.

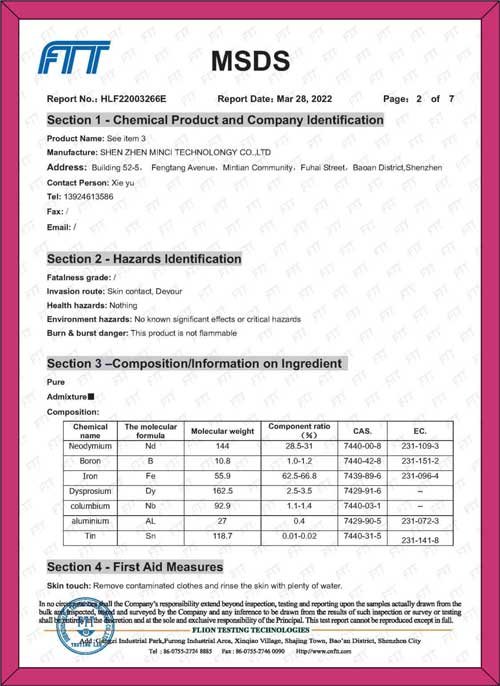

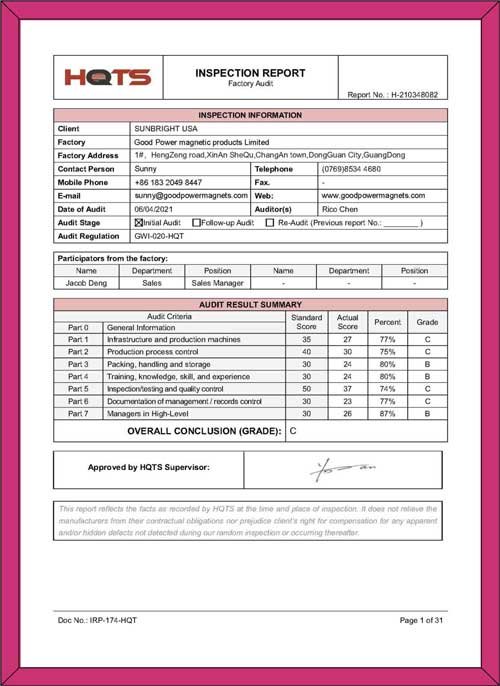

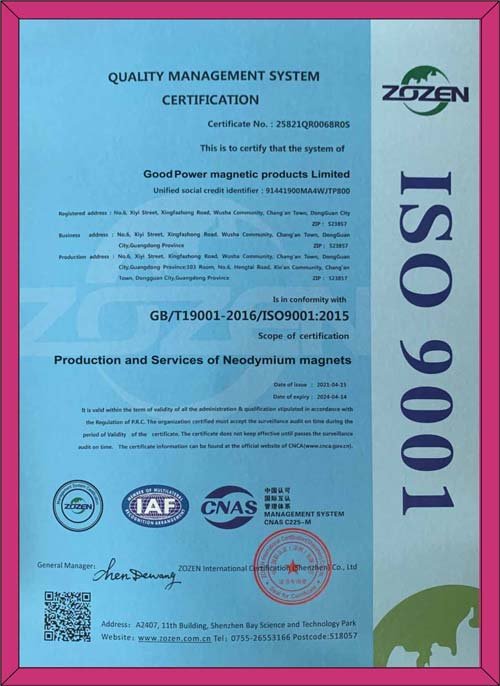

Global manufacturing standards

We have been in the neodymium magnet industry for 15 years. We have a low turnover of highly skilled teams of workers, many of whom have been with us for more than 10 years. Our ISO, MSDS and other certifications prove our commitment to quality.

Low MOQs

We have experience in docking large purchases while valuing orders from small and medium-sized businesses, and we are happy to help start-up companies grow, not just as business, but as partners.

Strict Quality Control

The final inspection is done in-house. Our quality control team has more than 10 quality control engineers and quality control equipment, who do nothing but final inspection of all our products before shipment.

Flexibility

We can produce custom sizes and shapes, quality, materials and packaging. We can easily meet all customer requirements outside of product specifications.

On-Time Delivery

We will never promise to deliver an order on an unreasonable schedule just to close a sale. Our customer support team will provide you with a delivery schedule prior to any purchase agreement.

What our customers benefit from

Request a quote for your next magnetic project

Become a partner of GP Magnets and astounding quality & unbelievable costs bring you more profits.

- One-stop magnet solution, from development, sampling to production

- Reasonable china magnetic parts price

- More than 15 years experience of magnetic products manufacturer china

- Fast reaction and Professional Communication