Neodymium disc magnet is obtainable in the disc and cylindrical shapes and are known for their remarkable magnetic properties that surpass those of all other permanent magnet materials. They boast of high magnetic strength, moderate pricing, and excellent performance at ambient temperatures. Ranging from miniature disc magnets with a 0.1-inch diameter to massive cylindrical magnets that can withstand up to 68 pounds, they offer a wide variety of options. The premium grades, which range from N30 to N52, are the most exceptional grades available in the market today.

Whether you need small, lightweight magnets for a DIY project, or large, high-strength magnets for an industrial application, we have you covered. Our neodymium disc magnets are carefully manufactured to ensure consistency and quality, and we offer competitive pricing and fast shipping to make your purchasing experience as convenient and hassle-free as possible.

GP Magnets provides powerful, long lasting and inexpensive arc neodymium magnets for your motors and magnetic assemblies.

Material: NdFeB, rare earth NdFeB arc magnets

Technology: a new type of sintered NdFeB magnets Process and equipment, such as band casting, HDDR technology.

Magnetic properties: A. High coercivity

B. (BH)max from 33 to 53 MGOe.

C. Maximum operating temperatures up to 230°C.

Grades: N33-N52, 33M-48M, 33H-48H, 30SH-45SH, 30UH-38UH, 30EH-35EH

Magnetic Direction: Axially Magnetized, Diametrally Magnetized, Thickness Magnetized,Multi-poles magnetized, Radial Magnetized. (Customized specific requirements magnetized)

Size: Customized Neodymium Magnet Sizes

Coating: NI, NICUNI, Zn, NiCU-Gold, copper, Epoxy, NICU-Epoxy, chemical, propylene, etc.

Applications: Industrial Magnet, Toy Magnet, Health Magnet etc.

| Dimension range(mm) | 0.5-3 | 3-6 | 6-30 | 30-120 | 120-400 |

| Min. (mm) | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 |

| Standard(mm) | ±0.1 | ±0.1 | ±0.2 | ±0.3 | ±0.5 |

The magnetization direction of neodymium disc magnets can vary depending on the manufacturer and the specific grade of the magnet. However, in general, neodymium disc magnets are magnetized through their thickness (i.e. from the top to the bottom or vice versa). This means that the magnetic poles are located on the flat circular surfaces at the top and bottom of the disc, and the magnetic field lines run in a circular pattern around the circumference of the disc.

| Material | Remanence(Br) | Coercive Force(Hcb) | Intrinsic Coercive Force(Hcj) | Max. Energy Product(BH Max.) | Working Temperatures | |

|---|---|---|---|---|---|---|

| Serial NO. | Grade | Kilogauss | Kilooersted | Kilooersted | MGOe | ℃ |

| N | N30 | 10.8-11.2 | 9.8-10.5 | ≥12 | 28-30 | ≤80 |

| N33 | 11.4-11.7 | 10.3-11.0 | ≥12 | 31-33 | ≤80 | |

| N35 | 11.7-12.1 | 11.0-11.3 | ≥12 | 33-35 | ≤80 | |

| N38 | 12.2-12.6 | 11.0-11.6 | ≥12 | 36-38 | ≤80 | |

| N40 | 12.6-12.9 | 11.0-11.6 | ≥12 | 38-40 | ≤80 | |

| N42 | 13.0-13.3 | 11.0-11.6 | ≥12 | 40-42 | ≤80 | |

| N45 | 13.3-13.7 | 11.0-11.6 | ≥12 | 43-45 | ≤80 | |

| N48 | 13.6-14.2 | 11.0-11.6 | ≥12 | 45-48 | ≤80 | |

| N50 | 14.1-14.5 | 10.4-11.4 | ≥11 | 48-50 | ≤70 | |

| N52 | 14.4-14.8 | 10.4-11.4 | ≥11 | 49.5-52 | ≤70 | |

| M | N35M | 11.7-12.1 | 11.2-11.5 | ≥14 | 33-35 | ≤100 |

| N38M | 12.2-12.6 | 11.4-11.7 | ≥14 | 36-38 | ≤100 | |

| N40M | 12.6-12.9 | 11.4-11.9 | ≥14 | 38-40 | ≤100 | |

| N42M | 13.0-13.3 | 11.4-11.9 | ≥14 | 40-42 | ≤100 | |

| N45M | 13.3-13.7 | 11.4-12.0 | ≥14 | 42-45 | ≤100 | |

| N48M | 13.6-14.2 | 11.4-12.0 | ≥14 | 45-48 | ≤100 | |

| N50M | 14.1-14.5 | 11.4-12.2 | ≥14 | 48-50 | ≤100 | |

| H | N33H | 11.4-11.7 | 10.3-11.0 | ≥17 | 31-33 | ≤120 |

| N35H | 11.7-12.1 | 10.8-11.4 | ≥17 | 33-35 | ≤120 | |

| N38H | 12.2-12.6 | 11.4-11.9 | ≥17 | 36-38 | ≤120 | |

| N40H | 12.6-12.9 | 11.4-11.9 | ≥17 | 38-40 | ≤120 | |

| N42H | 13.0-13.3 | 11.4-11.9 | ≥17 | 40-42 | ≤120 | |

| N45H | 13.3-13.7 | 11.4-11.9 | ≥17 | 43-45 | ≤120 | |

| N48H | 13.6-14.2 | 11.4-12.2 | ≥16 | 45-48 | ≤110 | |

| SH | N30SH | 10.8-11.2 | 10.1-10.6 | ≥20 | 28-30 | ≤150 |

| N33SH | 11.4-11.7 | 10.3-11.0 | ≥20 | 31-33 | ≤150 | |

| N35SH | 11.7-12.1 | 10.8-11.4 | ≥20 | 33-35 | ≤150 | |

| N38SH | 12.2-12.6 | 11.4-11.9 | ≥20 | 36-38 | ≤150 | |

| N40SH | 12.6-12.9 | 11.4-11.9 | ≥20 | 38-40 | ≤150 | |

| N42SH | 13.0-13.3 | 11.4-11.9 | ≥20 | 40-42 | ≤150 | |

| N45SH | 13.3-13.7 | 11.4-11.9 | ≥19 | 43-45 | ≤140 | |

| UH | N28UH | 10.4-10.8 | 9.8-10.2 | ≥25 | 26-28 | ≤180 |

| N30UH | 10.8-11.2 | 10.1-10.6 | ≥25 | 28-30 | ≤180 | |

| N33UH | 11.4-11.7 | 10.3-11.0 | ≥25 | 31-33 | ≤180 | |

| N35UH | 11.7-12.1 | 10.8-11.4 | ≥25 | 33-35 | ≤180 | |

| N38UH | 12.2-12.6 | 11.4-11.9 | ≥25 | 36-38 | ≤180 | |

| N40UH | 12.6-12.9 | 11.4-11.9 | ≥25 | 38-40 | ≤180 | |

| EH | N28EH | 10.4-10.8 | 9.8-10.2 | ≥30 | 26-28 | ≤200 |

| N30EH | 10.8-11.2 | 10.1-10.6 | ≥30 | 28-30 | ≤200 | |

| N33EH | 11.4-11.7 | 10.3-11.0 | ≥30 | 31-33 | ≤200 | |

| N35EH | 11.7-12.1 | 10.8-11.4 | ≥30 | 33-35 | ≤200 | |

| N38EH | 12.2-12.6 | 10.8-11.4 | ≥30 | 36-38 | ≤200 | |

| AH | N30AH | 10.8-11.2 | 10.1-10.6 | ≥35 | 28-30 | ≤240 |

Neodymium disc magnets are the strongest type of permanent magnets, making them suitable for heavy-duty applications where high magnetic force is required.

NdFeB magnets are highly resistant to demagnetization and can retain their magnetic properties for a long time.

Due to their compact size, neodymium magnets can be used in a wide range of applications, including industrial, commercial, and consumer products.

Compared to other types of strong magnets, neodymium magnets are relatively inexpensive, making them a cost-effective solution for many applications.

Neodymium magnets have a high energy density, meaning they produce a strong magnetic field in a small space. This makes them ideal for applications where space is limited.

NdFeB magnets can be small in size yet still have high magnetic strength, which makes them useful in applications where space is limited.

Neodymium magnet plating and coating can be better adapted to some harsh environments, such as ultra-low temperature, high temperature and humid environment.

GP Magnets is a leading manufacturer of high-quality neodymium magnets. With over 15 years of experience in the industry, we have established ourselves as a reliable and trusted source for magnets of all shapes and sizes.

Our extensive experience in optimizing production management allows us to offer high quality products at much lower prices than our competitors.

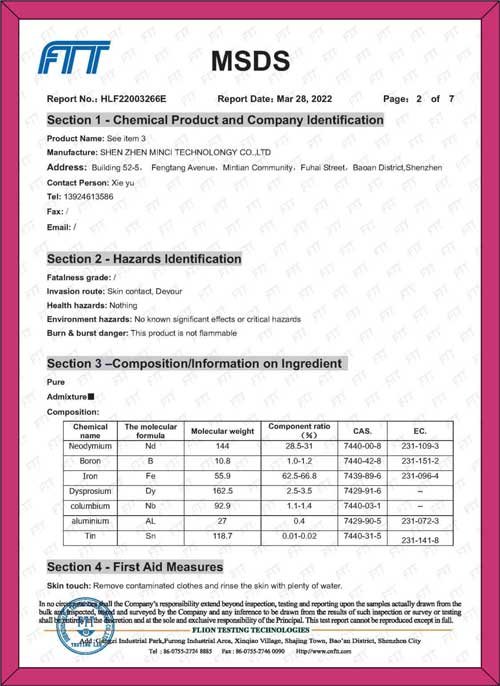

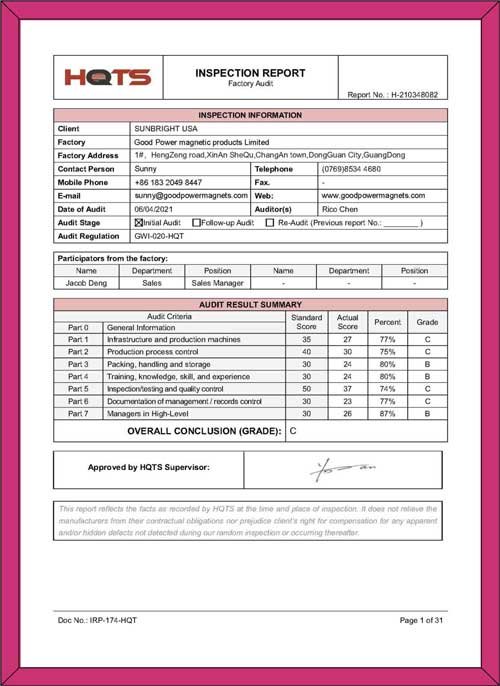

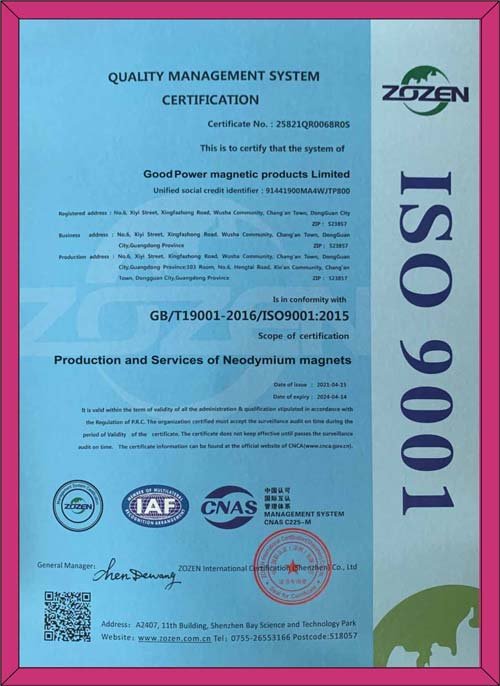

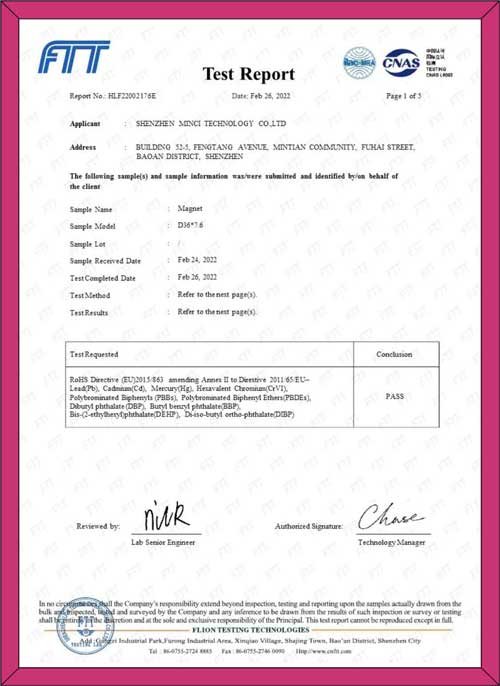

We have been in the neodymium magnet industry for 15 years. We have a low turnover of highly skilled teams of workers, many of whom have been with us for more than 10 years. Our ISO, MSDS and other certifications prove our commitment to quality.

We have experience in docking large purchases while valuing orders from small and medium-sized businesses, and we are happy to help start-up companies grow, not just as business, but as partners.

The final inspection is done in-house. Our quality control team has more than 10 quality control engineers and quality control equipment, who do nothing but final inspection of all our products before shipment.

We can produce custom sizes and shapes, quality, materials and packaging. We can easily meet all customer requirements outside of product specifications.

We will never promise to deliver an order on an unreasonable schedule just to close a sale. Our customer support team will provide you with a delivery schedule prior to any purchase agreement.

join the success

Become a partner of GP Magnets and astounding quality & unbelievable costs bring you more profits.

Communicate online using WhatsApp. We comply with security and privacy policies.